Oil and Gas Production: Stages, Equipment, and Cutting Edge Technology

The oil and gas production industry plays a pivotal role in the global economy, encompassing a complex journey from exploration to distribution.

In this guide, we will delve into the intricacies of oil and gas production, emphasizing the critical stages of upstream, midstream, and downstream processes.

Our focus will be on understanding the scope, processes involved, equipments, and the advanced technologies driving efficiency in the production of oil and gas products.

Introduction

Oil and gas production is a multifaceted process that involves extracting and refining crude oil and natural gas from wells, transforming them into essential petroleum products for consumer use.

This comprehensive procedure unfolds through systematic steps, commencing with site exploration, progressing to extraction, and culminating in the distribution of the final products to businesses and the general public.

As one of the world's largest sectors, the oil and gas industry significantly influences the global economy. However, despite its magnitude, the industry is not immune to volatility and fragility.

Recent developments between major oil producers have underscored the importance of bolstering oil and gas production to avert shortages and mitigate further price increases.

(Illustration image)

Stages of Oil and Gas Production

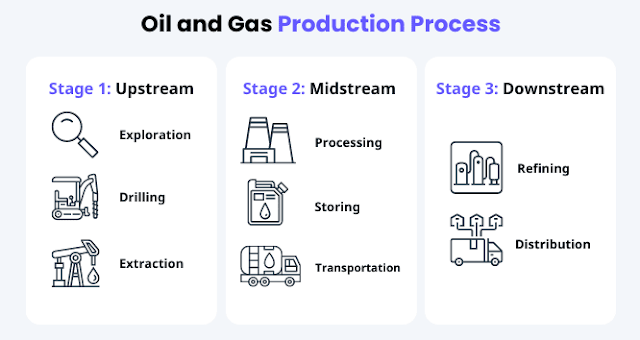

The oil and gas production process occurs in three distinct stages: upstream, midstream, and downstream.

Upstream is the initial phase, focusing on exploration and drilling. Midstream, the second stage, involves the production and distribution of gas. Downstream, the final stage, encompasses the processing and marketing of end products.

It is essential to remember that these three stages are interconnected in the supply chain of oil and gas production and distribution. Each stage is subject to regulations, with laws potentially varying depending on the location or state. Moreover, compliance with international agreements is also crucial.

To gain a deeper understanding of the stages of oil and gas production, let's further explore the following explanation.

Stage 1: Upstream

Upstream encompasses a series of activities involved in exploration, drilling, and extraction of crude oil and natural gas from underground reservoirs. Here are some key aspects of upstream activities:

Exploration

Drilling

Extraction

The upstream sector is a critical stage because its success in efficiently discovering and extracting oil and gas resources directly impacts production outcomes and profit potential for companies in this industry. Generally, upstream activities are closely related to the exploration and exploitation of natural resources.

Stage 2: Midstream

Midstream involves activities focused on the processing, storage, and transportation of oil and gas products from extraction locations (upstream) to processing and distribution facilities, and ultimately to end consumers (downstream). Some key aspects of midstream activities include:

Processing

Storage

Transportation

Midstream plays a crucial role in connecting upstream (extraction) and downstream (refining and distribution) activities in the supply chain of the oil and gas industry. Activities in the midstream sector ensure that these products can be efficiently moved from natural resources to markets or consumers, and this is an integral part of the global energy infrastructure.

Stage 3: Downstream

The downstream sector encompasses activities related to refining, processing, and distributing finished oil and gas products derived from extraction and processing. Here are some key aspects of downstream activities:

Refining

Distribution

The refined products are then distributed to various markets, industries, and end consumers. Distribution involves transporting these products through pipelines, tankers, trucks, railways, and other means of transportation.Final Storage

Marketing

The downstream sector aims to produce finished products ready for use by consumers or industries. These products include transportation fuels, lubricants, industrial raw materials, and other chemical products. Activities in the downstream sector play a crucial role in meeting the energy needs and industrial requirements globally.

Equipment: Oil and Gas Production

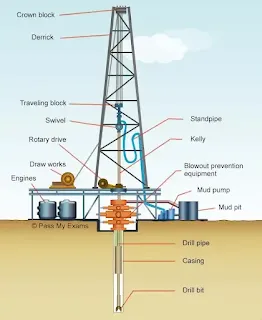

Drilling rig (illustration image, www.invt.com) - is one of the crucial equipment in oil and gas production

Production equipment in the context of the oil and gas industry comprises a collection of technical devices used to extract, process, and transport crude oil and natural gas from drilling wells to processing and distribution facilities.

This production equipment is designed to optimize efficiency and safety throughout various stages in the oil and gas production cycle. The following are some types of production equipment commonly used:

- Tank Vessels, encompass storage tanks used for storing oil and gas, along with gas condensers to condense gas into liquid form.

- Heat Exchangers, used to transfer heat between two fluids; types include shell and tube, plate, regenerative, and adiabatic wheel heat exchangers.

- Evaporators, used to convert liquids into vapor or remove liquid; types include natural/forced circulation, rising/falling film, climbing and a falling-film plate, multiple-effect, and agitated thin film evaporators.

- Air Coolers, used to cool fluids or gases by utilizing ambient air.

- Towers, may refer to separation or distillation equipment that separates different liquid components.

- Steel Pipes, used to transport oil, gas, or other fluids from one location to another.

- Geophysical Prospecting Equipment, used to gather data on the geological characteristics beneath the Earth's surface.

- Drilling and production equipment, include everything from drilling rigs to pumps necessary for the extraction of oil and gas.

- Refinery and chemical equipment, related to facilities that process crude oil into cleaner and more valuable products.

- Logging equipment, used to collect data and information about geological formations during well drilling.

- Offshore engineering equipment, specifically designed for use in oil and gas operations in offshore environments.

READ: Get to know the oil and gas production facilities and processes

Utilizing Cutting-Edge Technologies

The integration of new technologies in the oil and gas industry goes beyond traditional machinery, bringing forth numerous benefits for enhancing efficiency and maintaining safety in production processes. Some notable advanced technologies include:

1. Artificial Intelligence (AI)

- Role: AI assists oil and gas companies in various aspects, from surveying facilities to assessing reservoir values.

- Functions: It monitors machine conditions, customizes drilling processes, and executes plans that would otherwise be time-consuming if done manually.

- Benefits: Improved decision-making, enhanced operational precision, and the ability to handle complex tasks more rapidly.

2. Big Data Analytics

- Role: Big data analytics is employed to collect and analyze extensive datasets for informed decision-making.

- Functions: Companies can derive valuable insights, identify patterns, and optimize operations based on data-driven observations.

- Benefits: Informed decision-making, improved operational efficiency, and a deeper understanding of trends within the industry.

3. Internet of Things (IoT)

- Role: IoT allows the integration of various sensors crucial for efficient operational management.

- Functions: Electronic monitoring, a component of IoT, facilitates better field communication and enables real-time data collection and monitoring of pipes, storage facilities, transportation, and machinery.

- Benefits: Enhanced communication, improved operational visibility, and the ability to respond promptly to changes or issues.

4. Drones

- Role: Drones provide high-level visibility of wells, storage areas, and facilities.

- Functions: They expedite daily evaluations, ensure assessment accuracy, and offer a comprehensive view of vast or challenging-to-reach areas.

- Benefits: Increased efficiency in inspections, faster response to potential issues, and improved safety through reduced human exposure to hazardous environments.

In conclusion, in the dynamic landscape of oil and gas production, understanding the intricacies of the production process, the role of specialized equipment, and the integration of cutting-edge technologies is paramount. As the industry continually evolves, staying abreast of the latest advancements becomes a strategic imperative.

A judicious blend of traditional expertise and innovative solutions not only enhances operational efficiency but also contributes to safety, sustainability, and cost-effectiveness. By navigating the complex journey from upstream exploration to downstream distribution, the oil and gas sector is poised to embrace a future where technological prowess ensures a resilient and forward-thinking industry.

Photos credit: